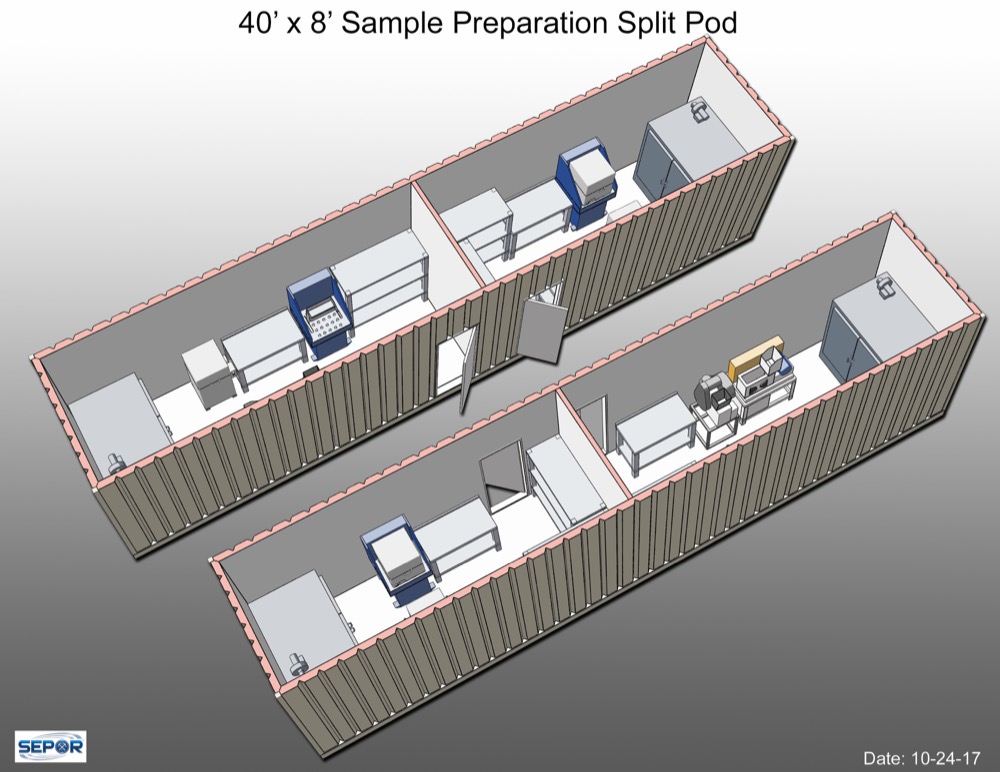

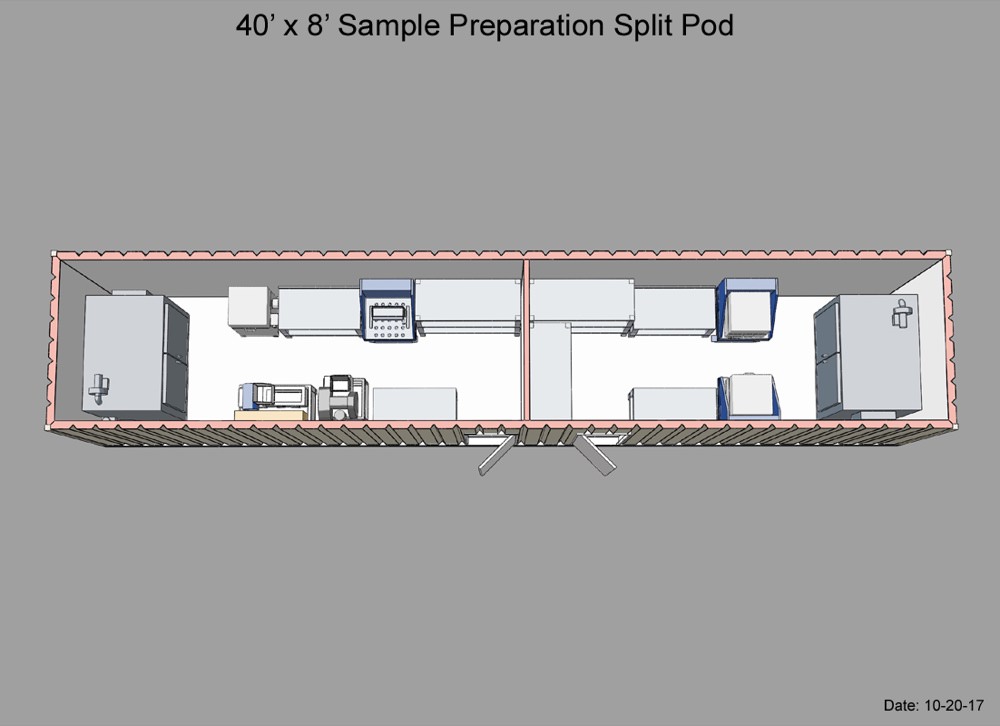

General Note: Internal GA displayed for each one of the modules is conceptual. Final design will strive to integrate the lab complex in the most efficient manner to optimize sample flow.

Intended for combined low grade/high grade ore bodies, plants processing concentrates and mines using the same facilities for ore, waste and exploration samples.

The split pod prep lab concept separates completely into two isolated sections. Each section has drying, crushing, and pulverizing capability. Dust control is all self-contained using downdraft benches with internal filters. Equipment can be modified to suit the needs of the project.

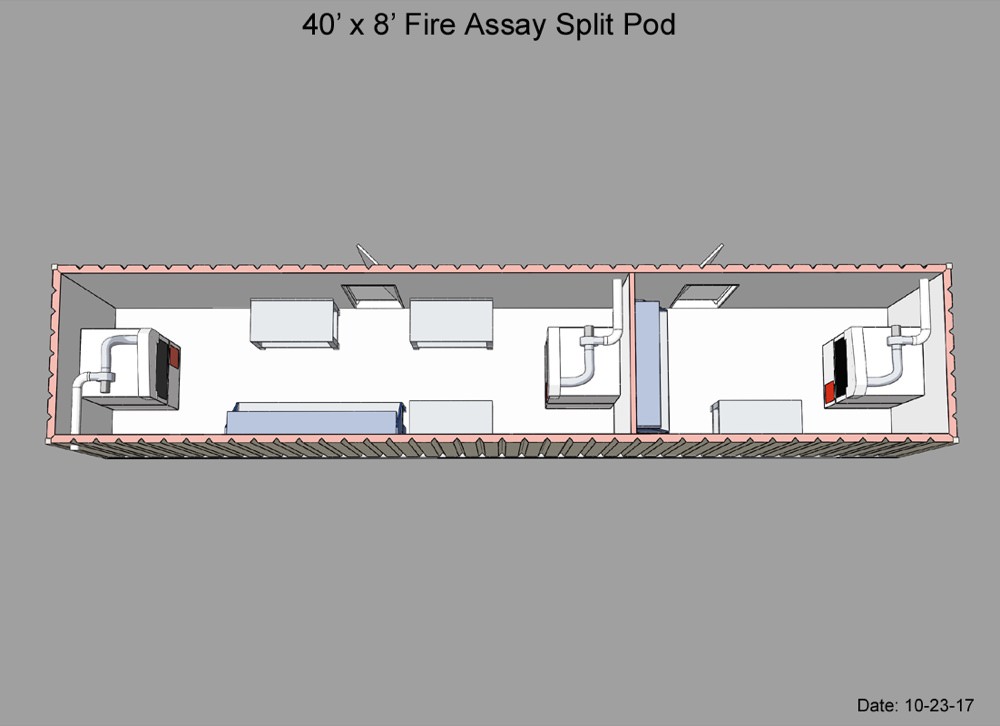

Using the same concept at the Split Pod sample preparation laboratory, the Split Pod Fire Assay lab has separated sections for high grade and low grade fire assays.

Furnace hoods are connected to an external lead oxide scrubber not shown in the illustration. Flux mixers and pouring tables are hooded.

In place of the Split Pod, the fire assay lab can be split into a furnace and instrument section.

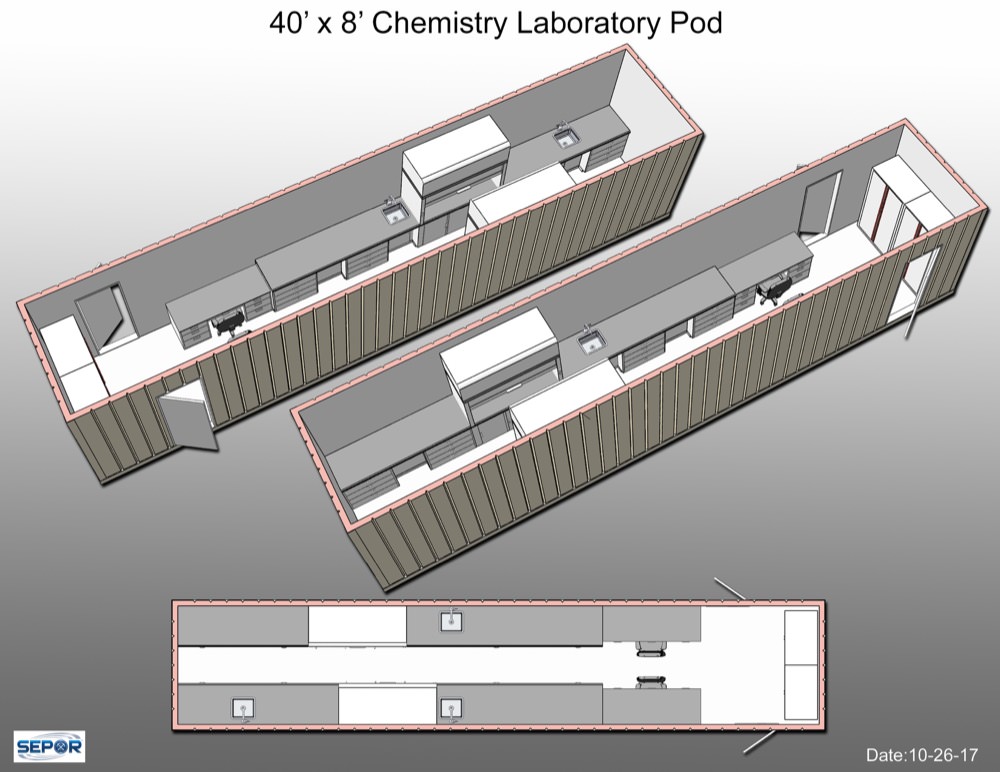

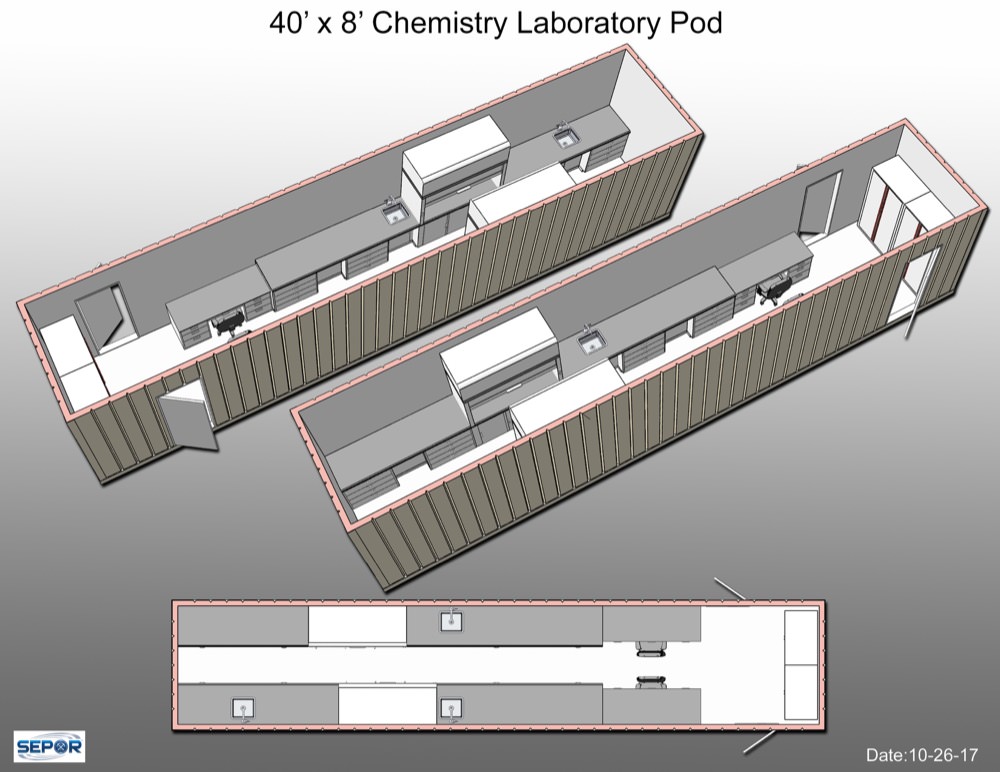

The Chemistry Lab is where the acid digestion of the fire assay beads and other concentrate digestions take place. This lab design has 6 foot acid resistant hoods, acid storage cabinets, epoxy sinks and 36” high benches. A small convection is designed into the lab as well, as well as a water purification system, fume scrubber and waste tank.

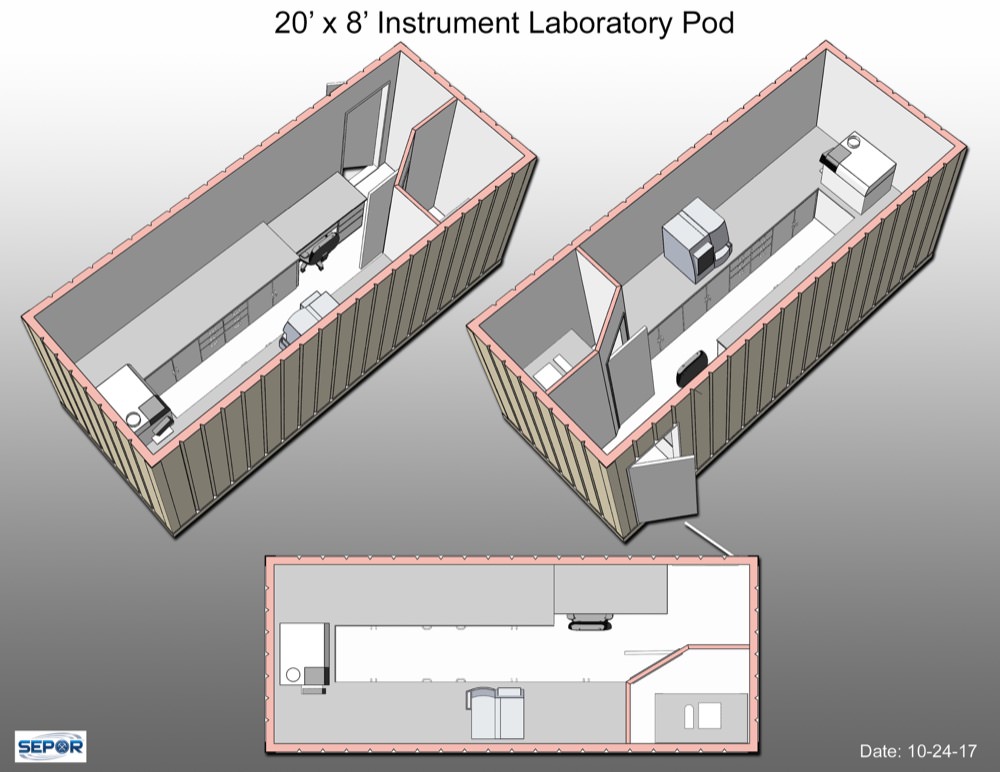

The 20’ Instrument Lab is designed to house the sensitive analytical instruments required to achieve the lowest detection limits. Finalize the analytical process with instruments such as Atomic Absorption, ICP, X Ray, UV-Vis or a microbalance in its own isolated balance room. You tell us what you want in it and Sepor will build the pod to fit.

Fume hood and water purification systems can also be installed. Units can come with waste water containment and neutralization systems as required.