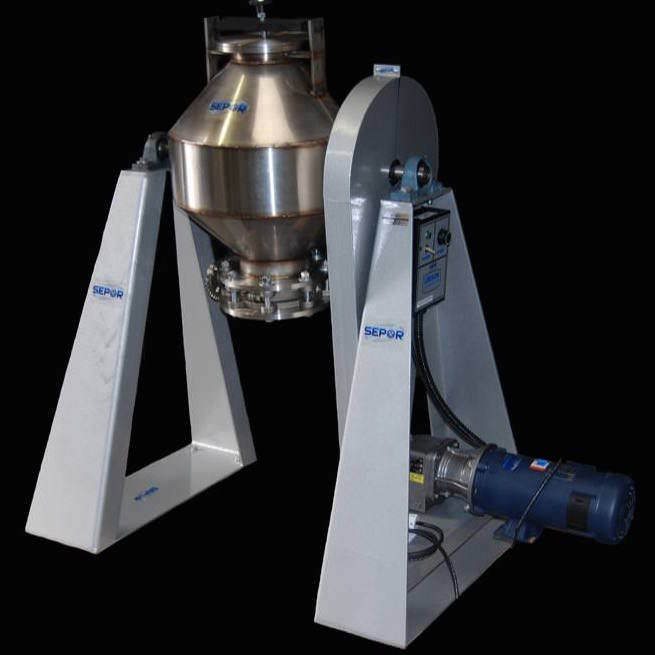

Sepor cone blenders are manufactured with all contact parts made of stainless steel. Standard configuration of the cone blenders includes a variable speed control, a V-belt drive, shaft mounted speed reducer or gear motor, mild carbon steel stands with 18 inches of floor clearance, butterfly type discharge valve, gasketed load opening plate secured by a crossbar with hand wheel, heavy duty pillow block shaft bearings and normal electrical configurations of 110V V/1Ph/50-60 Hz or 220 V/1 Ph/50-60 Hz. The mixing vessel is comprised of two opposed cones, welded to a cylindrical center band. The center band has two oversize machined trunnions, 180 degrees apart, welded to it to provide an axis about which the vessel rotates. The angle of the cone is 45 degrees. The size in inches of the cone blender indicates the diameter of the center band of the mixing cone.

Sepor Cone Blenders are easy to operate, with ample feed and discharge openings, easily cleaned between batches and are economical. Power costs are very low and no operator attention is required while blending is in process.

TECHNICAL SPECIFICATIONS (18″ – 42″, volume 1.1cf to 13cf)

EQUIPMENT MANUAL (36″ Cone Blender)

EQUIPMENT MANUAL (24″ Cone Blender)

EQUIPMENT MANUAL (18″ Cone Blender)