Lab and small-scale testing of dense media separation (DMS) has been a difficult task to accomplish as batch testing relies on heavy media solutions of high specific gravity (SG) salts that are expensive to purchase. Piloting requires tonnes of material to run through even the smalled of continuous DMS units.

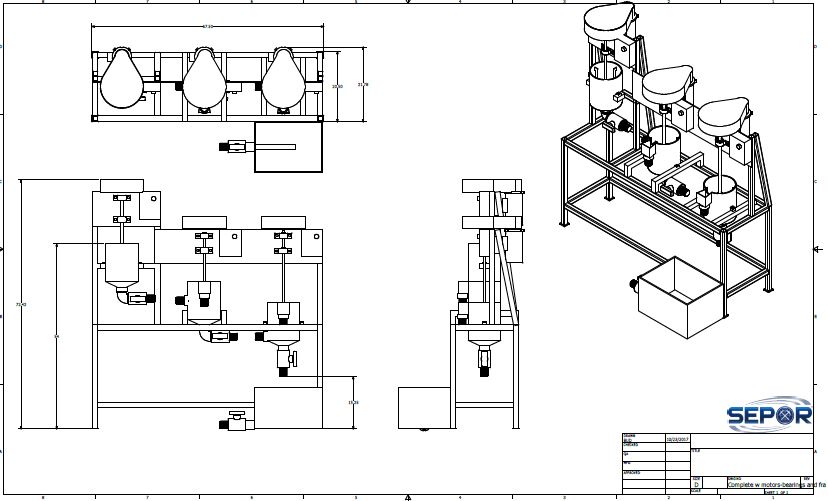

Sepor has designed and built this unique unit that combines the small sample size capability of bench testing with the low cost of using ferrosilicon or magnetite dense media in a slurry.

The material to be tested is conditioned in the top tank, then passed through either one or two stages of dense media slurry to remove sink and float. The sink from the first reactor can be either collected or sent through a second set to remove different SG material or used as a ‘cleaner’ for the material passed through the first DMS reactor.

Float and sink report to screen boxes on top of the DMS Media sump to separate out the ultrafine media from the product.

Contact Sepor at [email protected] with your process information and we will quickly respond with our recommendations.